"TheHondaBro" (wwaveform)

"TheHondaBro" (wwaveform)

03/17/2016 at 14:26 ē Filed to: Tags (max. 30)

5

5

23

23

"TheHondaBro" (wwaveform)

"TheHondaBro" (wwaveform)

03/17/2016 at 14:26 ē Filed to: Tags (max. 30) |  5 5

|  23 23 |

vicali

> TheHondaBro

vicali

> TheHondaBro

03/17/2016 at 14:30 |

|

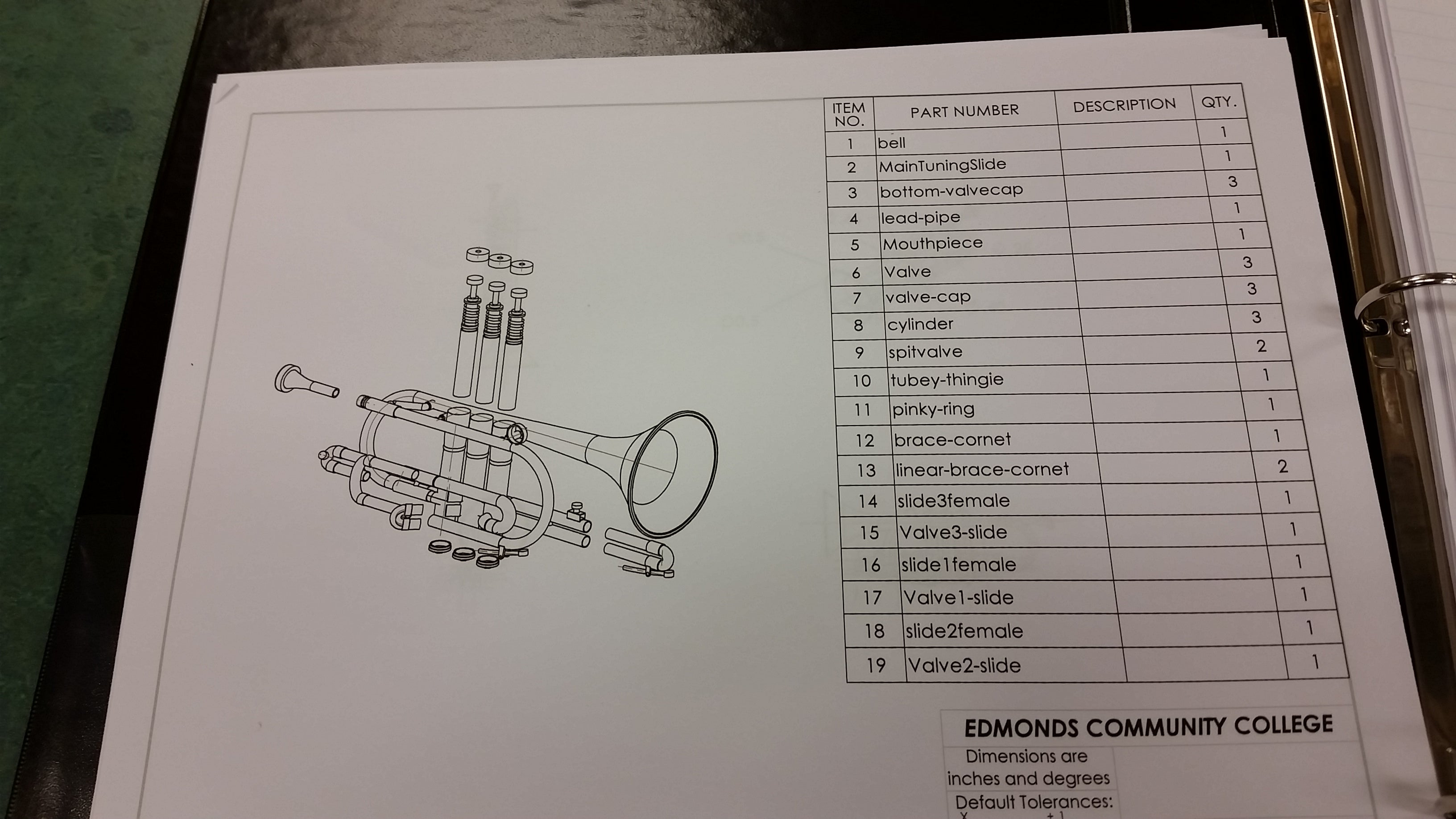

Thatís a nice looking tubey-thingie you got there..

dogisbadob

> TheHondaBro

dogisbadob

> TheHondaBro

03/17/2016 at 14:30 |

|

cool

yitznewton

> TheHondaBro

yitznewton

> TheHondaBro

03/17/2016 at 14:30 |

|

Spit valve yo

EDIT: oh... itís there, just not Ďsploded

TheHondaBro

> vicali

TheHondaBro

> vicali

03/17/2016 at 14:31 |

|

I didnít know what to call it.

BvdV - The Dutch Engineer

> TheHondaBro

BvdV - The Dutch Engineer

> TheHondaBro

03/17/2016 at 14:33 |

|

Ah, the all new Ikea KŲrnett

Jcarr

> TheHondaBro

Jcarr

> TheHondaBro

03/17/2016 at 14:33 |

|

vicali

> TheHondaBro

vicali

> TheHondaBro

03/17/2016 at 14:35 |

|

I had a friend who started her own instrument repair company - they used to go around to all the schools and get business from kids who hated their instruments, and their parents who had to pay to fix them.. it was quite lucrative I guess.

-this space for rent-

> TheHondaBro

-this space for rent-

> TheHondaBro

03/17/2016 at 14:38 |

|

Your valves need some holes

TheHondaBro

> -this space for rent-

TheHondaBro

> -this space for rent-

03/17/2016 at 14:41 |

|

Iím aware, but I had a fast-approaching deadline and Solidworks was being petulant with swept cuts.

just-a-scratch

> TheHondaBro

just-a-scratch

> TheHondaBro

03/17/2016 at 14:41 |

|

NSFW? I didnít know you could post pictures of a model showing off

all

her parts.

miadaman? yes please

> TheHondaBro

miadaman? yes please

> TheHondaBro

03/17/2016 at 14:47 |

|

Looks good, now do one in photoview 360 and frame it for generations to see and admire.

Tripper

> TheHondaBro

Tripper

> TheHondaBro

03/17/2016 at 14:55 |

|

-this space for rent-

> TheHondaBro

-this space for rent-

> TheHondaBro

03/17/2016 at 15:03 |

|

Solidworks is a fickle mistress.

uofime-2

> TheHondaBro

uofime-2

> TheHondaBro

03/17/2016 at 15:24 |

|

you forgot the balloons!

Biggus Dickus (RevsBro)

> TheHondaBro

Biggus Dickus (RevsBro)

> TheHondaBro

03/17/2016 at 15:29 |

|

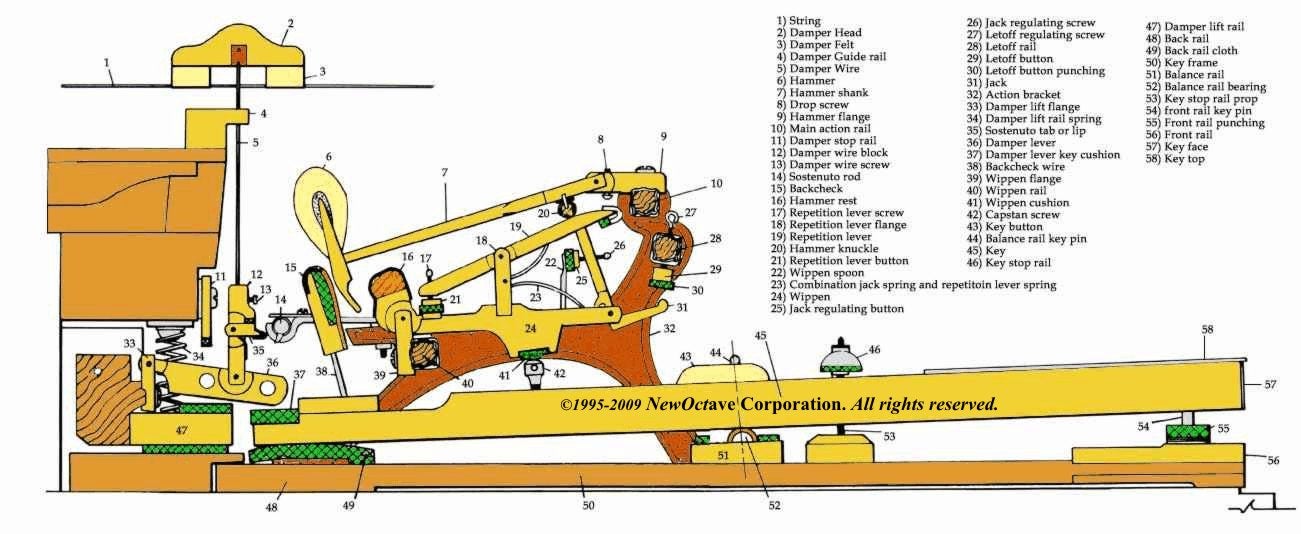

I want to post an exploded view of a grand piano buts just not practical. So have the key action:

RamblinRover Luxury-Yacht

> Biggus Dickus (RevsBro)

RamblinRover Luxury-Yacht

> Biggus Dickus (RevsBro)

03/17/2016 at 15:37 |

|

I need to get into the action (ha) on the one my mom and dad have in their living room. Some dozen keys are just pbbbllt, sticking.

Biggus Dickus (RevsBro)

> RamblinRover Luxury-Yacht

Biggus Dickus (RevsBro)

> RamblinRover Luxury-Yacht

03/17/2016 at 15:40 |

|

I wouldnít screw around with the action unless you really know what you are doing or this is just a cheapy grand that isnít played much.

Vlachen

> TheHondaBro

Vlachen

> TheHondaBro

03/17/2016 at 15:44 |

|

Swept Cut? Drop a plane perpendicular to what you want your thru hole axis to be and tangent to the valve body then an Extruded Cut will take care of it.

RamblinRover Luxury-Yacht

> Biggus Dickus (RevsBro)

RamblinRover Luxury-Yacht

> Biggus Dickus (RevsBro)

03/17/2016 at 15:48 |

|

Itís a perhaps ninety year old upright that isnít played much. Probably not much would be coming apart, and certainly nothing being readjusted, just a little peench of graphite in a few select places.

Vlachen

> -this space for rent-

Vlachen

> -this space for rent-

03/17/2016 at 15:48 |

|

This fact gets reaffirmed on almost an hourly basis in my world. What I always enjoy is the ridiculous rebuild times for (in my mind) simple features. For instance: 2 sketched bends on a sheet metal part. 15 fucking minute rebuild time. Turns out that one was based on the ďauto updating cutlistĒ option... on a 1 part cut list. Un-checking turns it from 15 min to 0.1 second rebuild.

TheNeonDriver - Now with More BMW!

> TheHondaBro

TheNeonDriver - Now with More BMW!

> TheHondaBro

03/17/2016 at 17:28 |

|

I miss working in Solidworks/Unigraphics..

AutoDesk Inventor is close, but Revit insnít the same..

TheNeonDriver - Now with More BMW!

> TheHondaBro

TheNeonDriver - Now with More BMW!

> TheHondaBro

03/17/2016 at 17:29 |

|

Donít use swept cuts, just generate a work plane in the center line of the cylinder, and remove material from there.

Montalvo

> TheHondaBro

Montalvo

> TheHondaBro

03/17/2016 at 17:43 |

|

Good old solidworks. From my experience I still like it more than Inventor or NX I-DEAS. The simulations were also pretty cool when testing parts for FSAE. Now I deal with AutoCad and Revit.